How Knack the no code database + AI Simplify Management and Modeling.

Manufacturing businesses today face a multitude of challenges, including streamlining operations, managing resources efficiently, and staying competitive in an evolving market. Many of these challenges stem from inefficiencies in data management and process optimization. Without the right tools, businesses often find themselves overwhelmed by complex workflows and disconnected systems.

This is where Knack + AI steps in. Knack, a powerful no-code database platform, combined with artificial intelligence, offers an innovative solution to simplify manufacturing management and modeling. By automating processes and providing real-time insights, Knack + AI empowers manufacturers to reduce operational costs, and enhance productivity.

In this blog, we’ll explore how this dynamic duo can revolutionize manufacturing management and provide actionable guidance for businesses ready to embrace the future.

1. Understanding Business Objects and Processes

To effectively manage a manufacturing system, it is critical to identify and understand the core business objects. These are the building blocks of your operational data and it may include:

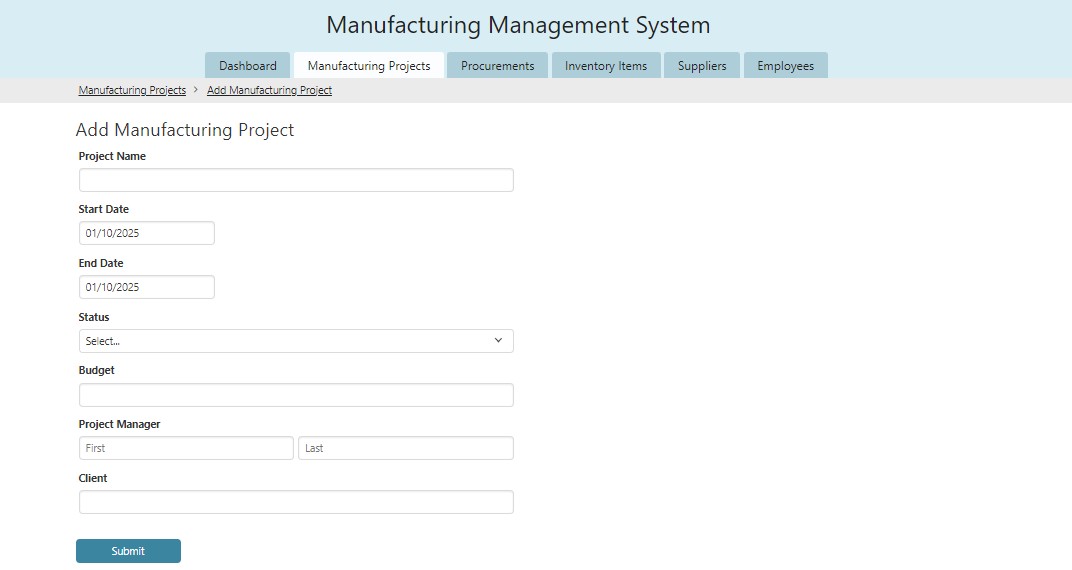

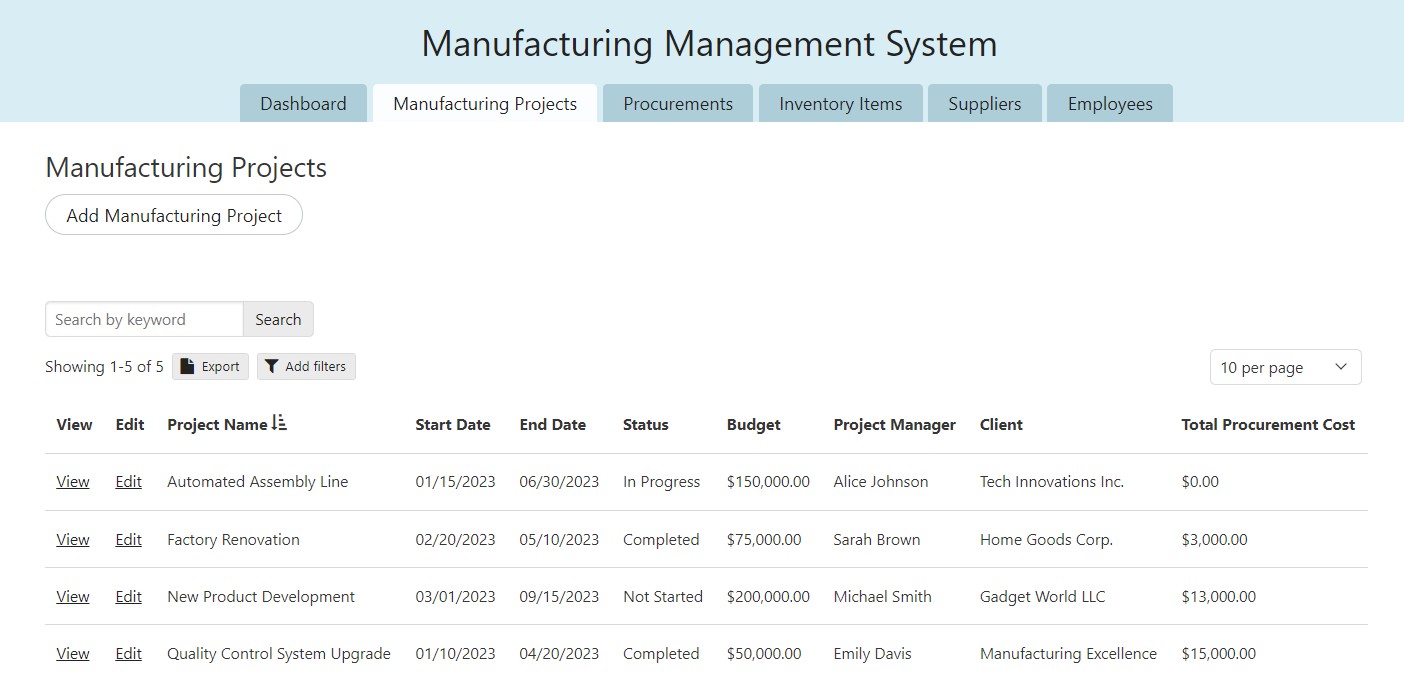

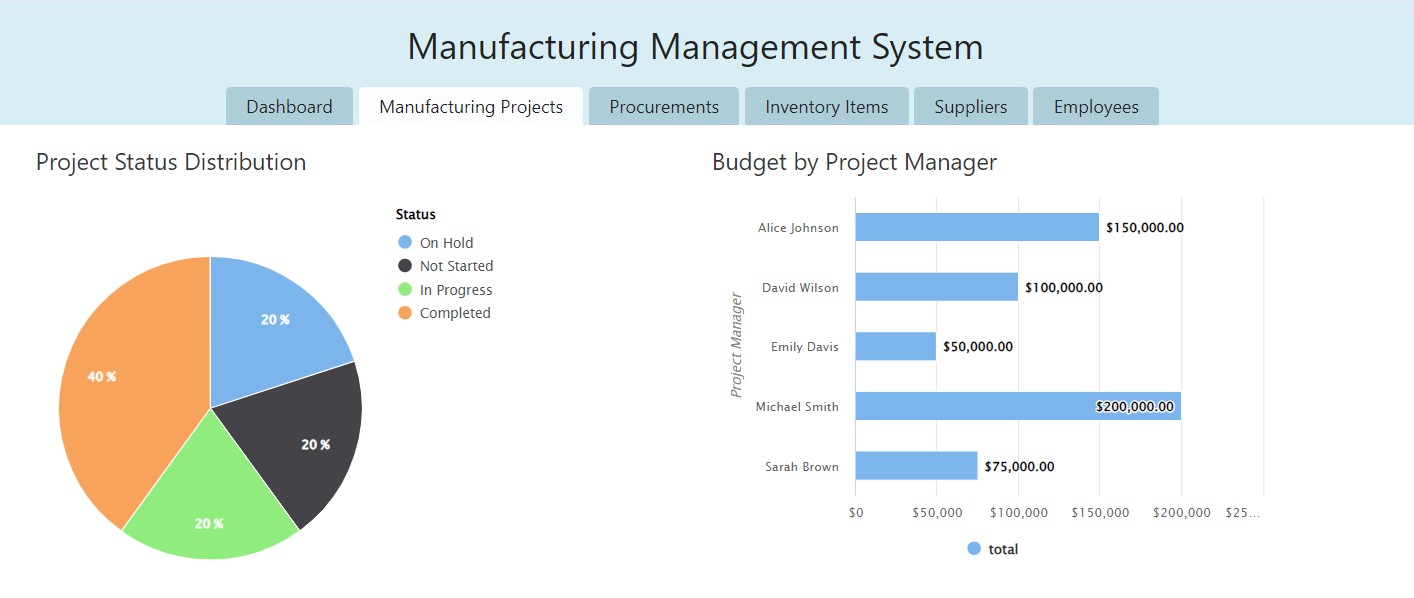

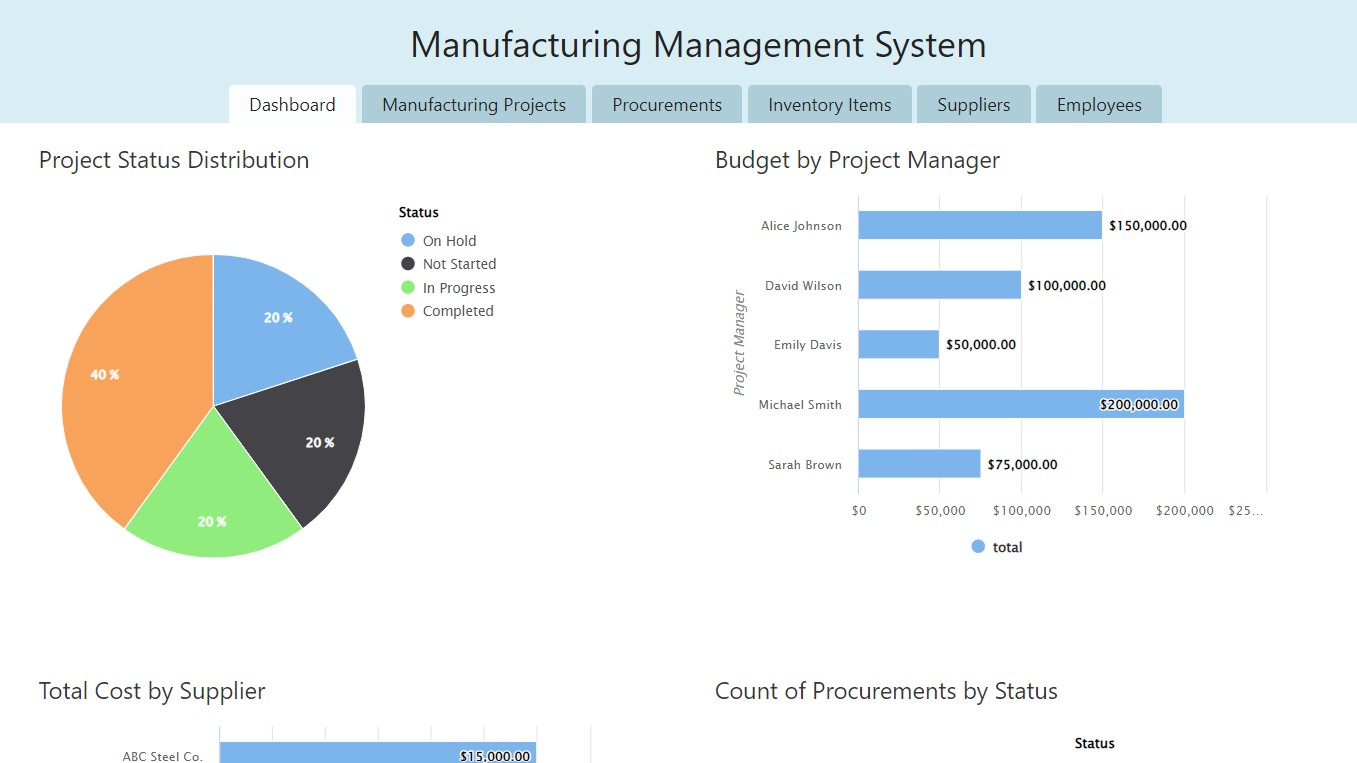

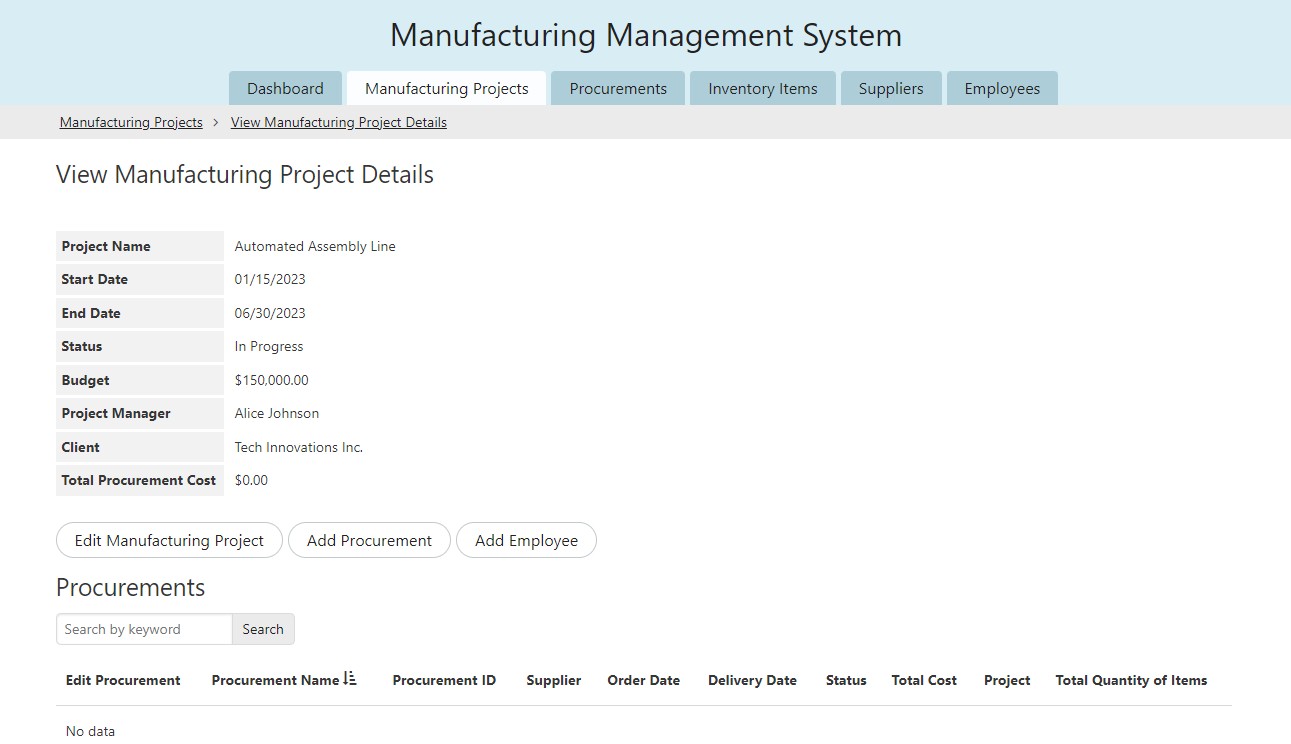

Manufacturing Projects: Track project budgets, timelines, clients, and statuses to ensure delivery on time and within scope.

Manufacturing Projects input data form in Knack

Manufacturing Projects records in Knack

Manufacturing Projects reporting in Knack

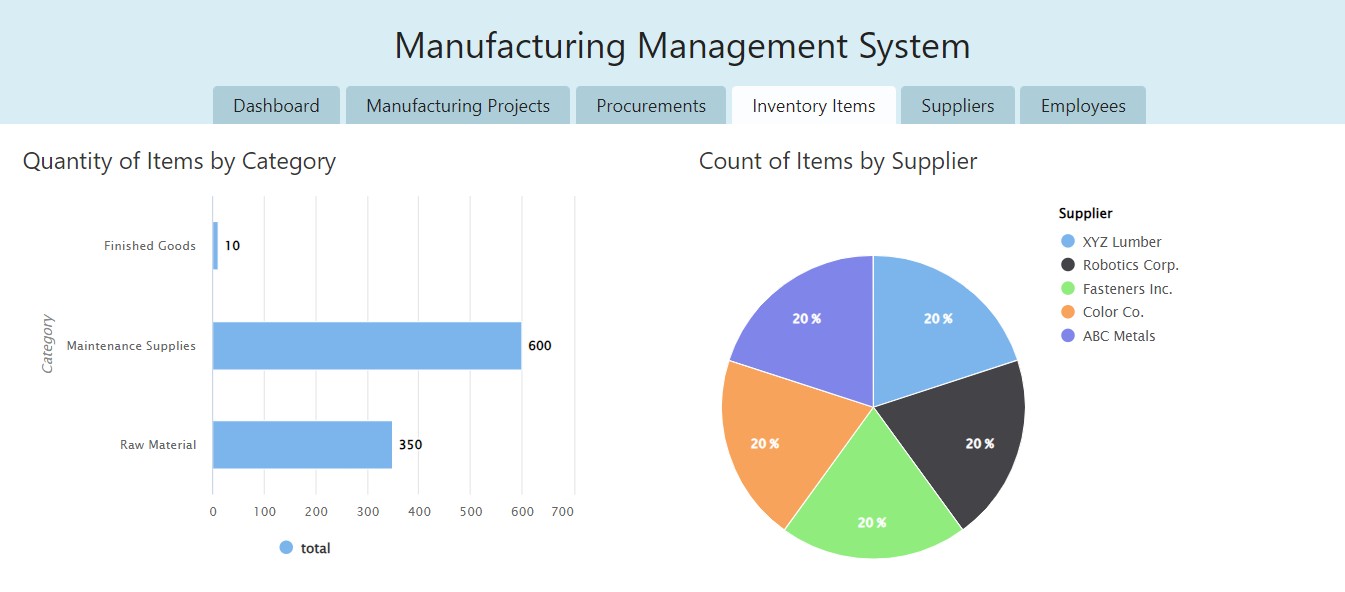

Inventory Items: Monitor categories, quantities, unit costs, and reorder levels to avoid stockouts or overstocking.

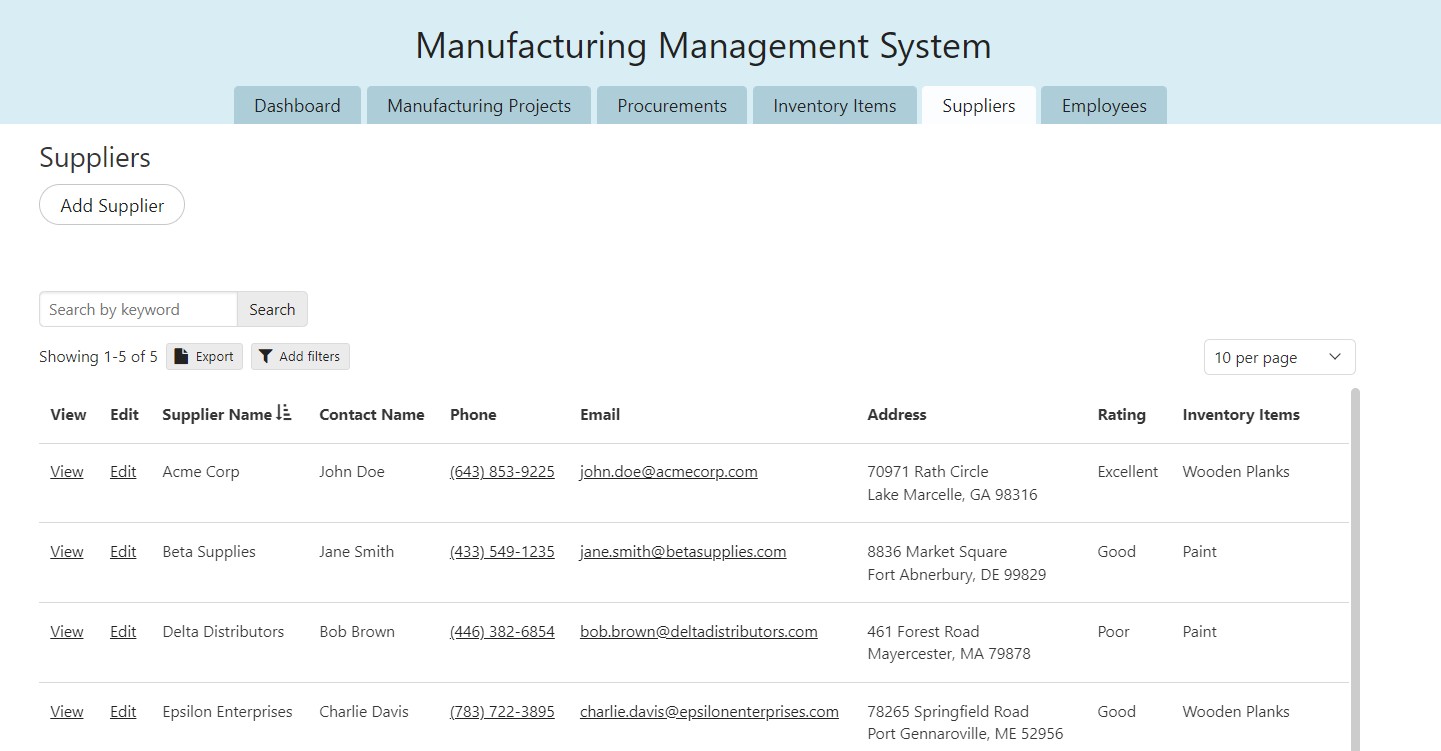

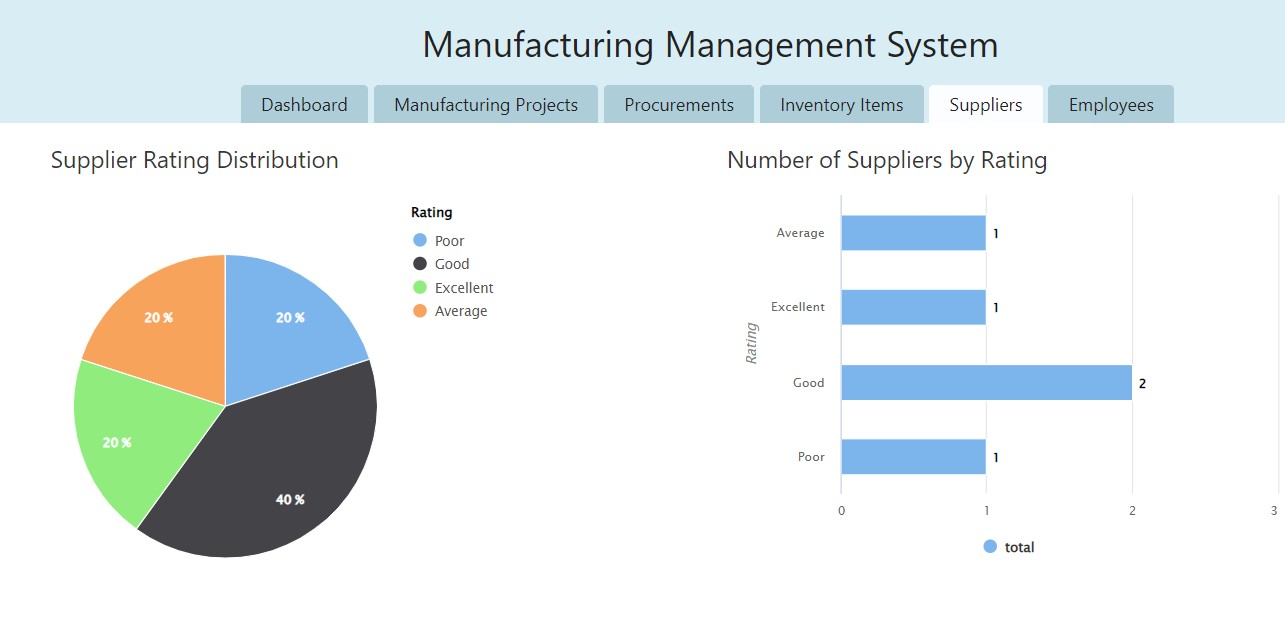

Suppliers: Maintain detailed records of supplier performance, contact information, and ratings to build reliable partnerships.

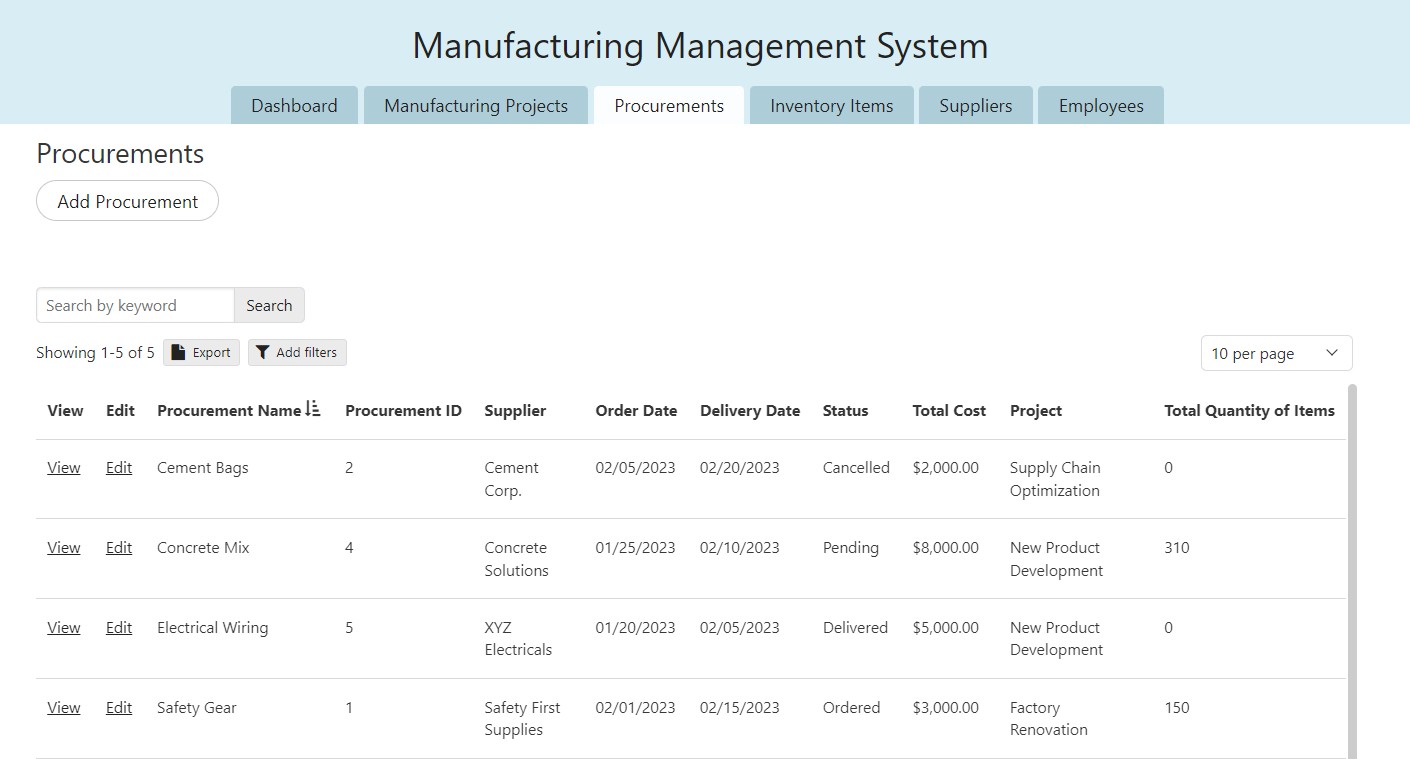

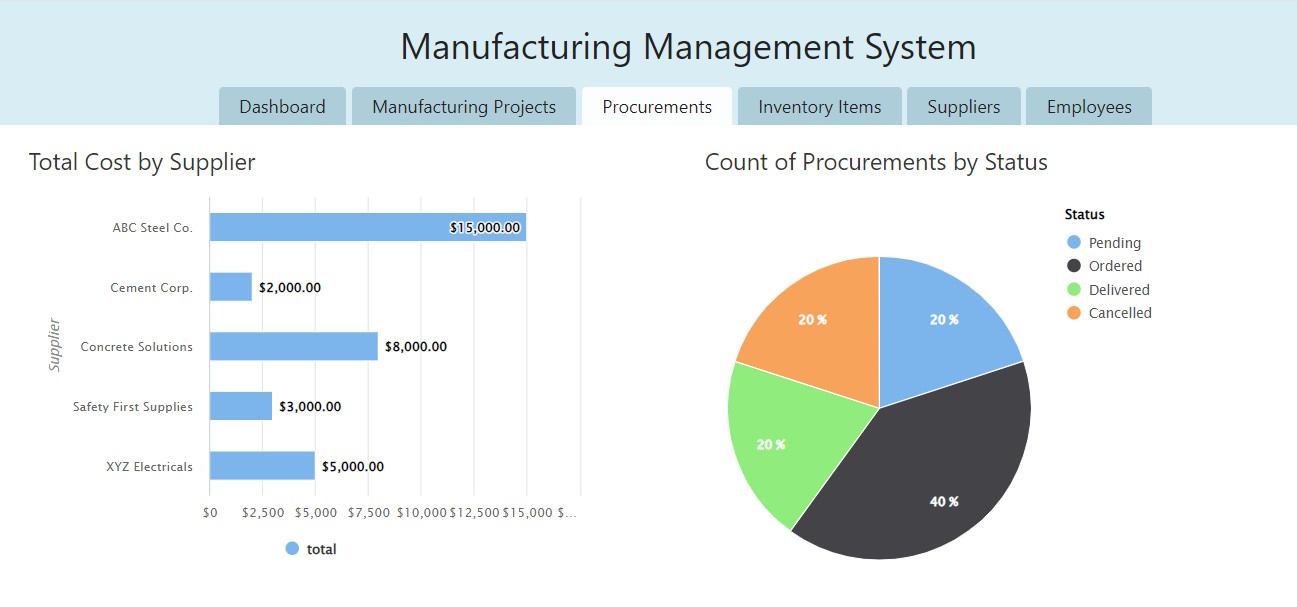

Procurements: Manage procurement orders, costs, statuses, and supplier relationships to streamline the supply chain.

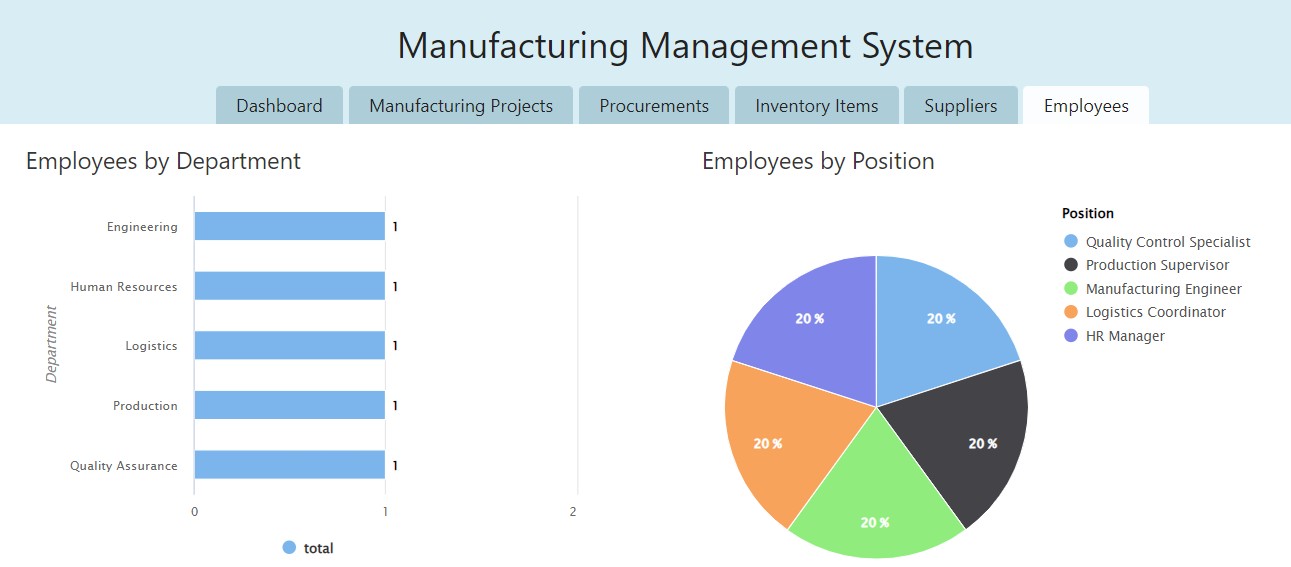

Employees: Record employee roles, departments, hire dates, and project assignments to optimize workforce allocation.

By clearly defining these business objects, manufacturers gain a structured framework that supports seamless operations and better decision-making.

Business processes define how business objects interact within your operations. Examples include:

Inventory Management: Automating reorder alerts and tracking item usage in real-time.

Supplier Evaluation: Using performance data to assess and optimize supplier relationships.

Procurement Workflow: Streamlining order placement, approval, and tracking.

Employee Management: Assigning roles to projects and monitoring productivity.

When processes are well-defined and aligned with business objects, organizations can minimize inefficiencies and unlock greater operational agility.

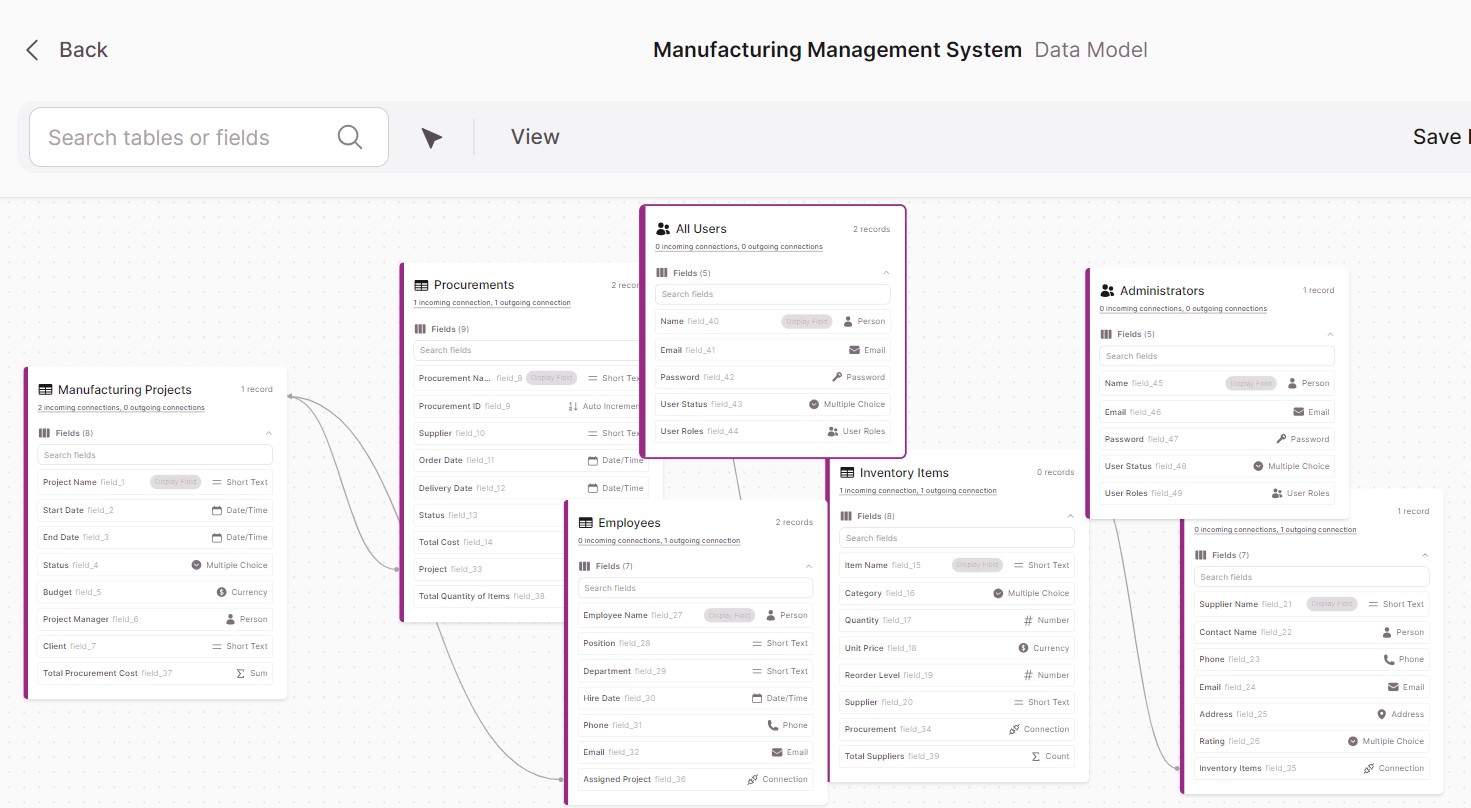

2. Logical Data Modeling with Knack

Knack’s intuitive no-code platform allows businesses to design and manage data models that reflect their unique operations. Its features include:

Visual Data Mapping: Easily define relationships between objects like inventory and suppliers.

Custom Dashboards: Create personalized views of key metrics such as project budgets and supplier ratings.

Scalable Structures: Adapt data models as your business grows, without requiring extensive technical expertise.

Leveraging AI for Data Structure Optimization

Our AI assistants add an extra layer of efficiency by accelerating your business objects identification and business processes creation/improvement based on your own data or knowledge.

Together, Knack and AI help businesses build robust, adaptable systems that drive operational success.

3. Practical Application: Manufacturing Management System

As example, the manufacturing management system, built using Knack, features:

Centralized Dashboard: A one-stop hub for tracking project statuses, procurement updates, and supplier costs.

Interactive Data Views: Detailed tables and charts that provide insights into inventory levels, employee assignments, and more.

Streamlined Interfaces: Easy-to-navigate modules for projects, inventory, suppliers, and employees.

These components enable manufacturers to visualize their operations and make informed decisions in real time.

Step-by-Step Implementation Using Knack:

Define Business Objects: Identify and map key entities like inventory items and suppliers.

Document Processes: Clarify workflows for procurement, inventory management, and employee allocation.

Build the Data Model: This is based on your logical data model.

Set Up Automations: Implement triggers for actions like reorder alerts and budget updates.

Test and Refine: Continuously optimize the system to meet evolving needs.

4. Advantages of No-code Platforms in Manufacturing

Accessibility: Empower non-technical staff to create and manage systems without coding expertise.

Flexibility: Quickly adapt to changing business requirements or market conditions.

Cost-Effectiveness: Save on development costs while maintaining high functionality.

5. Our Expertise and Services

With over five years of experience, Drinkizz has helped businesses across industries navigate digital transformation. Our expertise in no-code and AI solutions ensures that your manufacturing operations can achieve unparalleled efficiency.

We provide:

Strategic Consultation: Helping you identify critical business objects, processes, and rules.

Custom Training: Enabling your team to master Knack and AI tools for day-to-day operations.

End-to-End Support: From initial setup to ongoing maintenance, we’re with you every step of the way.

Our proven five-day implementation process includes:

Day 1: Analyze business needs and define key objects.

Day 2: Conduct solution studies and recommend the best tools.

Day 3: Build and test a robust data model.

Day 4: Configure the no-code database with security settings.

Day 5: Train your team and ensure seamless handoff.

The future of manufacturing is here. Simplify your operations, improve decision-making, and reduce costs with Knack + AI. Contact Drinkizz today to schedule a consultation and see how our tailored solutions can revolutionize your business.

Dzoulou Vinci Savitri.

CHIEF DIGITAL OFFICER (CDO) at Drinkizz & CONSULTANT

Email: [email protected] Phone number: (+84) 862965781

Download my PROFESSIONAL PROFILE (PDF format).

Thanks